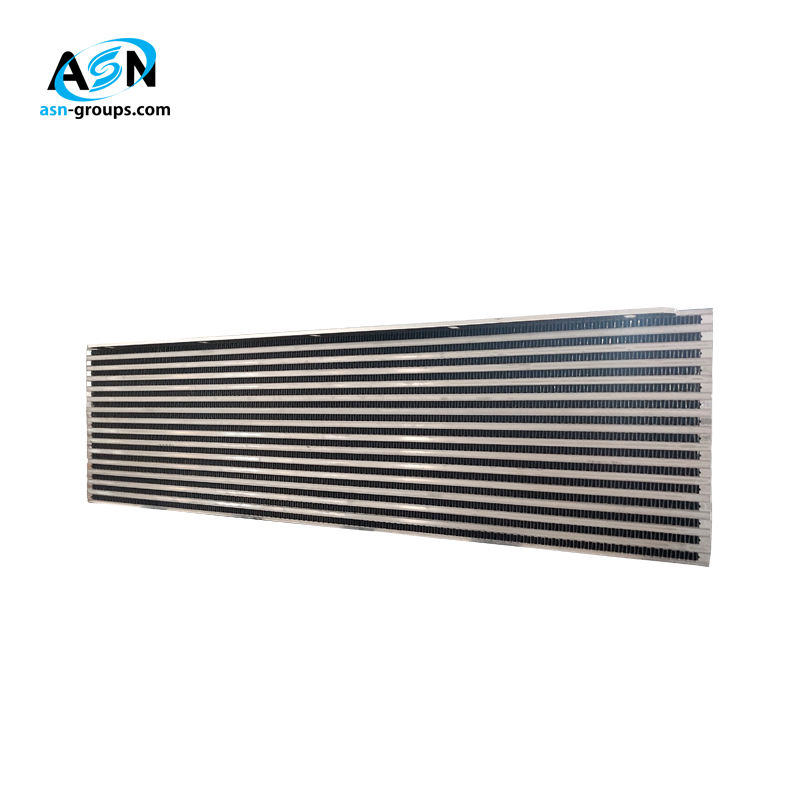

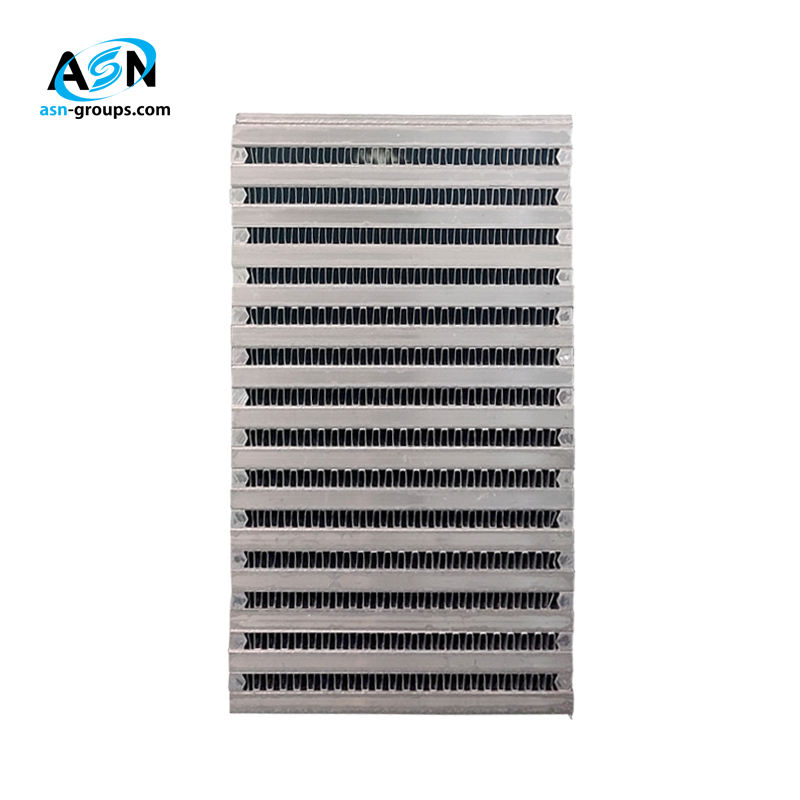

ASN Custom Plate-Fin Bar and Plate Heat Exchanger

Product Overview

The ASN custom plate-fin bar and plate heat exchanger is a high-accuracy, eco-friendly solution engineered for oil cooling and industrial applications. Built from durable aluminum, it offers excellent heat transfer performance, compact design, and reliable operation in demanding environments. With flexible customization options, it meets diverse industry requirements.

Key Features

-

Type: Plate Heat Exchanger (Bar and Plate, Plate-Fin Design)

-

Material: High-quality Aluminum

-

Core Components: Precision fins for enhanced heat transfer

-

Warranty: 1 Year

-

Machinery Test Report: Provided

-

Video Outgoing Inspection: Provided

-

Maximum Operating Temperature: 80℃

-

Working Temperature Range: -20℃ to +80℃

-

Fluid Compatibility: Oil

-

Weight: 5 KG

-

Dimensions: Fully customizable to customer requirements

-

Place of Origin: Jiangsu, China

-

Brand Name: ASN

Performance Highlights

-

Advanced plate-fin design ensures efficient and stable heat transfer

-

Customizable size and configuration to meet specific system needs

-

Lightweight aluminum structure for durability and corrosion resistance

-

Eco-friendly design aligned with modern industrial standards

Applications

-

Industrial oil cooling systems

-

Hydraulic and lubrication systems

-

Automotive and heavy machinery

-

Custom engineering projects requiring compact and efficient heat exchangers

Packaging & Delivery

-

Selling Units: Single item

-

Packaging: Export-standard protection (custom options available)

Purchase Assurance

-

Reliable quality backed by testing and inspection reports

-

Flexible customization to suit your project needs

-

Competitive and eco-friendly design trusted by global industries

FAQ

1. Can the heat exchanger be customized in size and design?

Yes, the dimensions and configuration can be tailored to meet specific customer requirements.

2. What makes the plate-fin design more effective?

The plate-fin structure provides a larger surface area for heat transfer, resulting in higher efficiency compared to conventional designs.

3. What industries typically use this type of heat exchanger?

It is widely used in industrial oil cooling, hydraulic machinery, and heavy equipment where efficient and compact cooling is essential.

4. How is product quality ensured?

Each unit is supplied with a machinery test report and video outgoing inspection to guarantee performance and reliability.