In the age of energy efficiency and sustainable living, air heat exchangers have become the unseen hero. Whether located in industrial plants, commercial buildings, or residential homes, these systems silently transfer heat between air streams, saving energy, stabilizing indoor temperatures, and improving air quality. The concept is simple: they capture heat that would otherwise be wasted and use it to pre-treat supply air. However, behind this simple idea lies a complex thermodynamic design, precise engineering, and advanced materials technology. Understanding how an air heat exchanger works allows us to appreciate how modern ventilation and HVAC (heating, ventilation, and air conditioning) systems deliver both comfort and sustainability.

The Core Principle: Energy Exchange through Airflow

The principle of thermal energy transfer underlies every air heat exchanger. Air heat exchangers operate by passing two air streams—one warm and one cold—through a heat exchange surface. This surface acts as a thermal bridge, allowing energy to flow from the warmer to the cooler air without mixing. This means that stale exhaust air from the building can preheat or pre-cool the incoming fresh air, significantly reducing the energy required for heating or cooling.

This process relies on conduction and convection. Conduction transfers heat through walls (often metal or polymer), while convection circulates the air, increasing the rate of exchange. By controlling the direction and speed of airflow, the system ensures that maximum thermal energy transfers from one stream to the other efficiently.

A key feature of air heat exchangers is their airtight design. During heat exchange, the two air streams do not mix, preventing cross-contamination. This makes them ideal for spaces such as hospitals, laboratories, and clean rooms, where air purity is crucial.

Anatomy of an Air Heat Exchanger

An air heat exchanger is more than just a box with fans and vents. It consists of a coordinated system of components designed to optimize thermal performance and minimize energy loss. The key elements include:

-

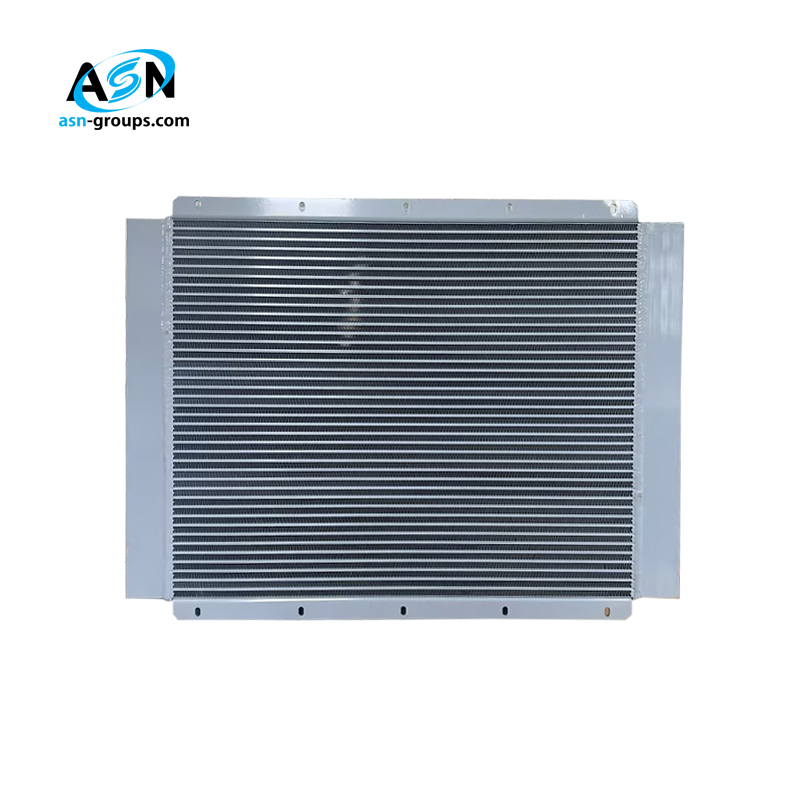

Heat Exchange Core: The heart of the system, often made of aluminum, copper, or polymer plates. This core facilitates the transfer of heat between air streams.

-

Fans and Ducts: These ensure continuous airflow through the exchanger. Balanced fan operation prevents backflow and maintains air pressure stability.

-

Filters: Installed on both intake and exhaust sides to prevent dust and particles from clogging the exchanger or contaminating the indoor air.

-

Condensate Drain: When warm, moist air meets a cool surface, condensation forms. A drain system prevents water buildup and corrosion.

-

Control System: Modern exchangers use intelligent sensors to monitor temperature, humidity, and air quality, adjusting fan speed or bypass modes for optimal performance.

In advanced systems like heat recovery ventilators (HRVs) or energy recovery ventilators (ERVs), the design also includes moisture exchange membranes that allow controlled humidity transfer, creating balanced indoor environments.

How Heat Transfer Actually Happens

The working principle of an air heat exchanger can be divided into distinct stages:

-

Airflow Setup: The system brings in fresh air from outside and expels stale indoor air simultaneously.

-

Temperature Gradient Formation: The exhaust air is typically warmer in winter or cooler in summer, creating a temperature difference between the two streams.

-

Heat Transfer Process: As the air streams pass through the exchanger’s core, energy flows through the separating surfaces—warming or cooling the incoming air.

-

Exhaust and Supply: The conditioned fresh air is distributed into the indoor environment while the used air is discharged outside.

The efficiency of this process is determined by the thermal conductivity of materials, the surface area of the exchanger, and airflow velocity. Well-designed systems can achieve up to 90% heat recovery efficiency, dramatically reducing HVAC energy demands.

Main Types of Air Heat Exchangers

Different designs suit different environments and applications. The choice depends on building type, required air volume, and the desired efficiency level.

• Plate Heat Exchangers (Crossflow or Counterflow):

These are the most common. They use stacked metal or polymer plates forming alternating channels for warm and cool air. Counterflow configurations are more efficient, as air streams move in opposite directions, maintaining a stronger temperature gradient.

• Rotary Wheel Heat Exchangers:

These systems use a rotating wheel coated with a heat-absorbing material. As the wheel spins, it captures heat from the exhaust air and transfers it to the incoming stream. Some wheels also allow moisture recovery, making them suitable for ERVs.

• Run-Around Coil Systems:

Here, two coils are connected by a closed loop filled with a heat transfer fluid (like glycol). The warm air heats the fluid in one coil, which then circulates to the other coil to preheat incoming air. This design is ideal for buildings where air ducts cannot be positioned closely.

• Heat Pipe Exchangers:

These use sealed copper tubes filled with refrigerant. Heat from the exhaust side vaporizes the fluid, which then condenses on the cooler intake side, releasing heat. They’re compact and highly effective for localized ventilation systems.

Each type balances cost, maintenance, and energy recovery differently. For instance, rotary wheels offer higher efficiency but require moving parts, while plate exchangers are static and maintenance-free.

業界を超えたアプリケーション

The versatility of air heat exchangers extends far beyond household ventilation. Their design has been adapted for a broad range of industries and climatic conditions.

• Residential Buildings:

Modern homes equipped with HRVs or ERVs use air heat exchangers to maintain indoor comfort while reducing energy bills. These systems are especially valuable in well-sealed, energy-efficient homes where natural ventilation is limited.

• Commercial and Office Buildings:

Office complexes, hospitals, and schools use large-scale air-to-air heat exchangers integrated into HVAC systems to maintain air quality and temperature stability.

• Industrial Applications:

Factories and data centers use industrial heat exchangers to manage heat generated by equipment, prevent overheating, and recover thermal energy for reuse.

• Automotive and Aerospace:

In vehicles and aircraft, compact air heat exchangers manage cabin temperature and engine air intake systems, contributing to fuel efficiency and emissions reduction.

Efficiency and Sustainability: Why It Matters

Air heat exchangers are a key technology in achieving energy efficiency and carbon reduction goals. By recycling otherwise wasted thermal energy, they can reduce heating and cooling energy requirements by 30–70%. This translates directly into lower CO₂ emissions and operating costs.

In regions with harsh winters, such as Northern Europe and Canada, heat recovery systems are often required by building codes because they provide comfort without overheating. Similarly, in hot and humid climates, heat recovery systems balance temperature and humidity, reducing the need for air conditioning.

Their contribution goes beyond energy savings. Air heat exchangers improve indoor air quality (IAQ) by continuously introducing oxygen-rich air while filtering out pollutants. This is crucial in urban environments, where ventilation often conflicts with energy conservation goals.

Technological Innovations and Material Advances

Modern air heat exchangers have evolved dramatically with technology. Key advancements include:

-

High-Conductivity Composite Materials: Replacing traditional metals with advanced polymers and aluminum alloys to improve heat transfer and reduce weight.

-

Smart Control Systems: Sensors and AI-driven software now optimize operation based on occupancy, outdoor conditions, and energy tariffs.

-

Modular Construction: Enables easy integration into different HVAC architectures and simplifies maintenance.

-

Anti-Fouling and Antimicrobial Coatings: Extend system lifespan and maintain air hygiene by preventing mold or bacterial growth.

Future trends are leaning toward hybrid exchangers that combine air-to-air and heat pump technologies, enabling even greater energy recovery and climate adaptability.

Real-World Performance and Testing

The performance of an air heat exchanger is measured by its heat recovery efficiency (HRE), which is the ratio of recovered energy to total available energy. Other key parameters include pressure drop, air leakage, and moisture recovery rate. Laboratories and certification bodies such as Eurovent, AHRI, and ISO 16890 provide standardized testing for accurate performance comparisons.

High-quality heat exchangers are designed for low pressure drop—meaning less fan power is required to move air through the system. They also incorporate a balanced airflow system that maintains a stable internal temperature, even with rapidly fluctuating external conditions.

Challenges and Maintenance Considerations

Despite their many advantages, air heat exchangers require proper design and upkeep. Common challenges include:

-

Frost Formation: In cold climates, condensation can freeze inside the exchanger, blocking airflow. Solutions include preheaters or defrost cycles.

-

Dust and Debris Accumulation: Regular filter replacement and coil cleaning are necessary to maintain efficiency.

-

Pressure Imbalance: If fan speeds are unbalanced, air leakage or reduced recovery efficiency may occur.

-

Material Degradation: Prolonged exposure to humidity or corrosive environments can reduce performance unless corrosion-resistant materials are used.

Preventive maintenance schedules and monitoring systems can mitigate these issues, ensuring long-term reliability and energy savings.

Environmental and Economic Impact

From a sustainability perspective, the popular adoption of air heat exchangers is one of the most effective ways to conserve energy. Compared to solar panels or geothermal systems, heat exchangers have a quicker payback period: typically, it will take 2-5 years for the system to pay back. This is because the cost of utility is reduced.

They also have a significant impact on green building certifications like LEED, BREEAM, and WELL. Including ventilation that recovers heat helps buildings to have energy-saving potential, interior air quality, and thermal comfort.

From an economic perspective, their low operating costs and long lifespan (often exceeding 20 years) make them an ideal investment for developers and facility managers.

The Future of Air Heat Exchange Systems

As global climate policies become more stringent and efficiency standards for buildings increase, air heat exchangers will continue to progress. The integration of IoT (Internet of Things) systems with the platform enables predictions of maintenance and real-time energy monitoring. Combined with renewable power sources and smart grids, they can facilitate self-governing, low-emission building systems.

Also, research is progressing toward materials that are nanostructured and have a phase that changes to enhance thermal conductivity while minimizing bulk. These new designs will likely increase the efficiency of recovery to 100%, which will define the possible designs of HVAC systems.

The Invisible Bridge Between Comfort and Conservation

An air heat exchanger may not seem significant–a metal box that is tucked inside a ventilation system–but it represents one of the most impressive solutions in modern technology. By re-recycling the energy that was previously lost in the atmosphere, it balances the scales between efficiency, comfort, and environmental stewardship. Whether located in a suburban home, an office on high, or an industrial facility, air-to-air heat exchangers consistently demonstrate that sustainability is both practical and powerful.

As buildings become more intelligent and energy becomes more worthwhile, the common air heat exchanger will still be the undisclosed cornerstone of effective, breathing architecture. Every breath in and every watt of it counts.