Industrial refrigeration systems have experienced greater pressure than ever before. The equipment is becoming more compact, the heat loads are still increasing, and the efficiency targets are no longer removable; they are now part of the regulations, operating expenses, and system design from the beginning. In this context, traditional air heat exchanger solutions are increasingly approaching their maximum capacity.

This shift has led to an increase in attention toward microchannel plate heat exchangers that are evacuated. Their adoption is not the result of a brief popularity trend, but rather a response to genuine engineering impediments. As manufacturing and HVAC systems progress, these heat exchangers are re-conceptualizing the practicality of cooling in modern applications.

The Limits of Conventional Air Heat Exchanger Designs

For decades, finned-tube air heat exchangers have been the default option in industrial refrigeration and HVAC systems. They’re common, easily accessible, and simple to create. However, comfort does not always have to translate into appropriateness in different situations.

As the volume of power system components increases, the design of fins begins to show significant limitations. Their larger size makes it difficult to compact into a small space in compact equipment design. The efficiency of heat transfer in the air increases only marginally as the size increases, resulting in a diminishing return. Additionally, heavier structures increase the complexity of installation and the overall weight of the system.

Another obstacle is the durability of the system. Traditional methods of joining and material interfaces can fail under long-term thermal cycling, vibrations, and corrosion. Eventually, this results in the potential for leakage, reduced performance, and higher costs of maintenance. Today, in modern industrial settings that require high uptime and consistent performance, these issues are increasingly difficult to explain.

What Defines a Microchannel Plate Fin Air Heat Exchanger

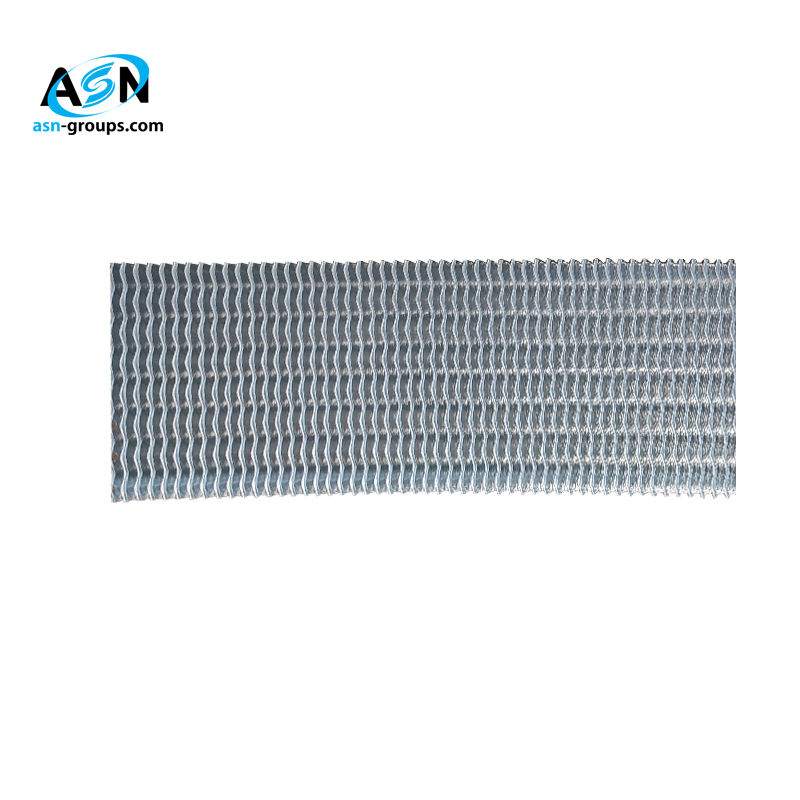

A microchannel plate finned air heater takes a different approach to heat transfer that is primarily based on direct contact. Instead of relying on relatively large tubes, it employs multiple small flow passages distributed across flat surfaces. These microchannels have a dramatic effect on the heat transfer area while still maintaining a uniform distribution of fluids.

The plate’s fin structure increases the efficiency of the air side. Thin aluminum flaps serve as efficient flowpaths for air, maximizing the interaction between the air and the heat transfer surfaces. The outcome is a small compact exchange that can transfer large thermal loads in a smaller space.

This structural difference is not intended to be aesthetically pleasing. Microchannel plate design allows engineers to reconsider the way they arrange systems, reduce the size of components, and improve the thermal efficiency of their designs without increasing the energy expenditure.

Why Vacuum Brazing Changes the Game

The design of a dressing alone cannot ensure its effectiveness. The manufacturing quality is of equal importance, especially in microchannel structures with high density. This is the location of the importance of vacuum brazing.

Vacuum brazing combines aluminum components in a sealed, oxygen-free environment. Unlike the conventional method of brazing, this method doesn’t require a flux, which means that no chemical compounds remain in the heat exchanger’s interior. This lack of residue directly enhances the corrosion resistance and long-term neatness of the product.

Additionally, the vacuum brazing process guarantees consistent, powerful joints across the entire core. In microchannel plate heat exchangers that are designed for small air volumes, the joint’s integrity is of paramount importance. Joints that are weak or in disarray can detrimentally affect the performance and reduce the life of the device. Vacuum brazing reduces the likelihood of these risks by providing consistent attachment across the exchanger.

How Microchannel Design Drives Higher Cooling Efficiency

Efficiency gains from microchannel plate fin air heat exchangers come from several reinforcing factors rather than a single improvement. Smaller channels increase heat transfer coefficients, allowing more heat to be exchanged over a shorter distance. Uniform flow distribution reduces localized hot spots and improves overall thermal balance.

At the system level, these efficiencies translate into tangible benefits:

-

Higher cooling capacity within a compact core size

-

Reduced refrigerant or coolant volume requirements

-

Lower air-side pressure drop, decreasing fan energy consumption

These improvements allow designers to meet cooling targets without oversizing components, which is increasingly important in energy-conscious industrial environments.

Compact Design as a System-Level Advantage

Compactness is often described as a convenience, but in industrial cooling systems, it is a strategic advantage. Smaller heat exchangers free up space for other components, simplify equipment layout, and support modular system designs.

In retrofit or upgrade projects, space constraints often determine whether an efficiency improvement is feasible at all. Microchannel plate fin air heat exchangers make such upgrades possible by delivering higher performance without expanding physical dimensions.

Transport and installation also benefit. Lighter, more compact exchangers reduce handling complexity and structural support requirements, contributing to lower overall project costs.

Reliability and Corrosion Resistance in Harsh Environments

Industrial and HVAC environments are rarely gentle. Heat exchangers are exposed to humidity, temperature fluctuations, airborne contaminants, and continuous operation. Reliability under these conditions depends as much on internal cleanliness and material stability as on external design.

Vacuum-brazed aluminum microchannel cores offer strong resistance to corrosion because they eliminate flux-related residues that can trap moisture and initiate chemical reactions. The uniform joint structure also improves resistance to vibration and thermal cycling.

Over long service periods, these characteristics help maintain consistent cooling performance and reduce the risk of unexpected failure—an essential requirement in mission-critical industrial systems.

Typical Industrial and HVAC Applications

The advantages of vacuum-brazed microchannel plate fin air heat exchangers make them suitable for a wide range of applications where efficiency, reliability, and space optimization matter.

Common application areas include HVAC air cooling systems, electronics and power equipment thermal management, industrial machinery cooling, and energy-related systems requiring stable heat dissipation. In each case, the exchanger’s compact size and high efficiency support modern design expectations without compromising durability.

Quality Assurance and Manufacturing Standards

High-performance heat exchangers demand equally high manufacturing standards. Precision fabrication, controlled brazing processes, and thorough inspection are not optional—they define whether theoretical performance becomes real-world reliability.

Machinery test reports and outgoing inspection videos provide tangible proof that each exchanger meets design and performance requirements. These measures help engineers and procurement teams verify quality before installation, reducing uncertainty and project risk.

Quality assurance is particularly important for vacuum-brazed microchannel plate fin air heat exchangers, where internal structure cannot be visually inspected after assembly.

Why ASN Vacuum-Brazed Microchannel Plate Fin Air Heat Exchangers Stand Out

ASN vacuum-brazed microchannel plate fin air heat exchangers are designed with these industrial realities in mind. Their aluminum microchannel cores are manufactured using controlled vacuum brazing processes to ensure clean, corrosion-resistant structures and strong, consistent joints.

Each unit is supported by a one-year warranty, machinery test reports, and outgoing inspection documentation. This focus on verifiable quality reflects a commitment to reliability rather than short-term performance claims. For industrial and HVAC applications where consistency matters as much as efficiency, this approach provides practical assurance.

Industrial cooling efficiency is no longer defined by size alone. As systems become more compact and performance demands increase, heat exchanger technology must evolve accordingly. Vacuum-brazed microchannel plate fin air heat exchangers represent a clear response to these challenges.

By combining compact design, high heat transfer efficiency, and reliable manufacturing processes, they redefine what modern industrial cooling systems can achieve. Rather than pushing traditional designs beyond their limits, these exchangers offer a more balanced, future-ready solution—one aligned with the real demands of contemporary industrial and HVAC applications.