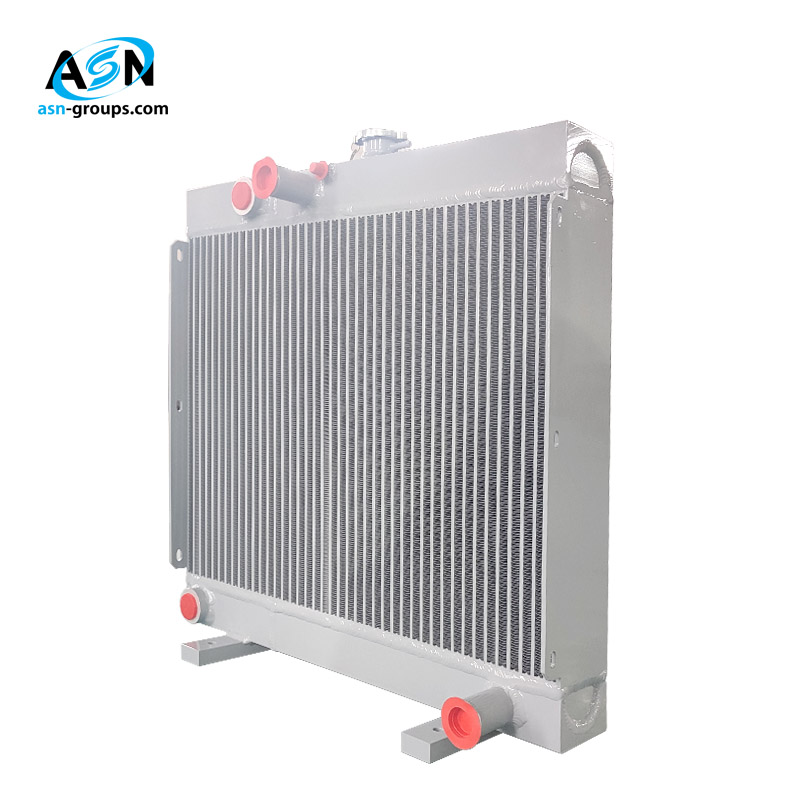

ASN Vacuum-Brazed Microchannel Plate-Fin Air Heat Exchanger

Product Overview

This vacuum-brazed microchannel plate-fin air heat exchanger delivers superior cooling performance with compact design and reliable construction. Engineered for demanding industrial and HVAC applications, it ensures efficient heat transfer, enhanced durability, and corrosion resistance.

Key Features

-

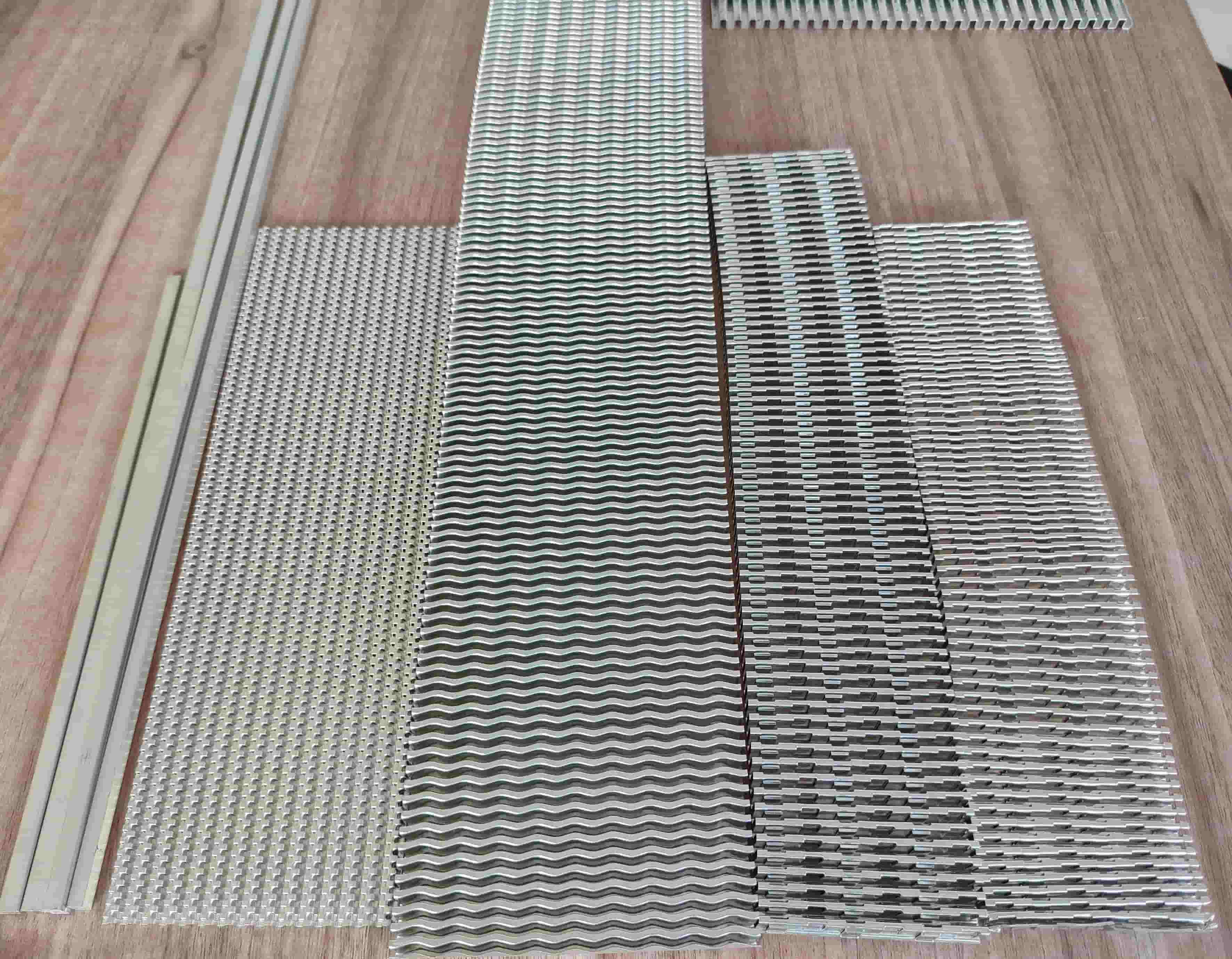

Type: Plate Heat Exchanger, Vacuum-Brazed Microchannel Plate-Fin

-

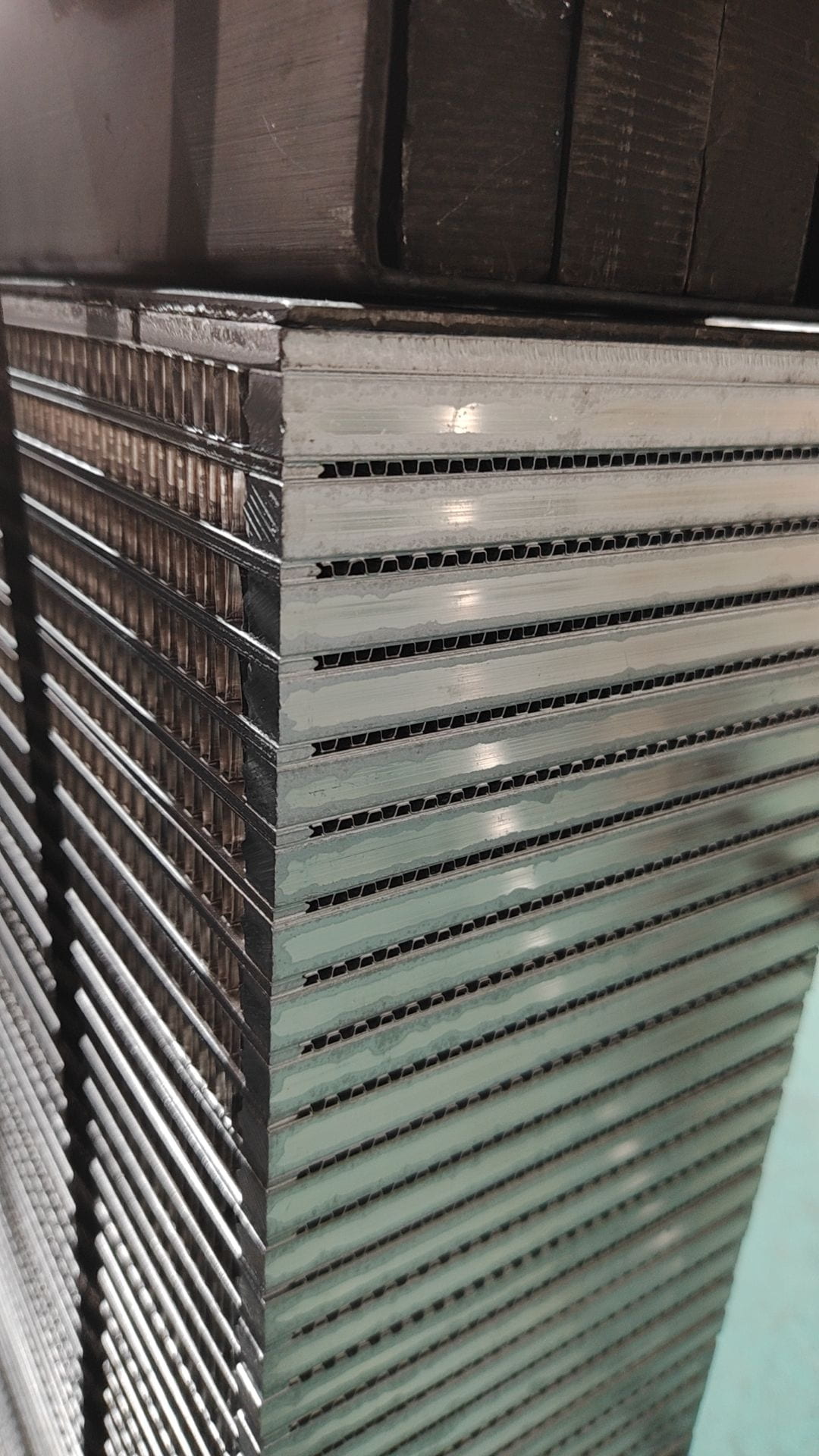

Material: Aluminum (aluminum fin) — vacuum brazing ensures clean, corrosion-free cores

-

Warranty: 1 Year

-

Machinery Test Report: Provided

-

Video Outgoing Inspection: Provided

Performance Highlights

-

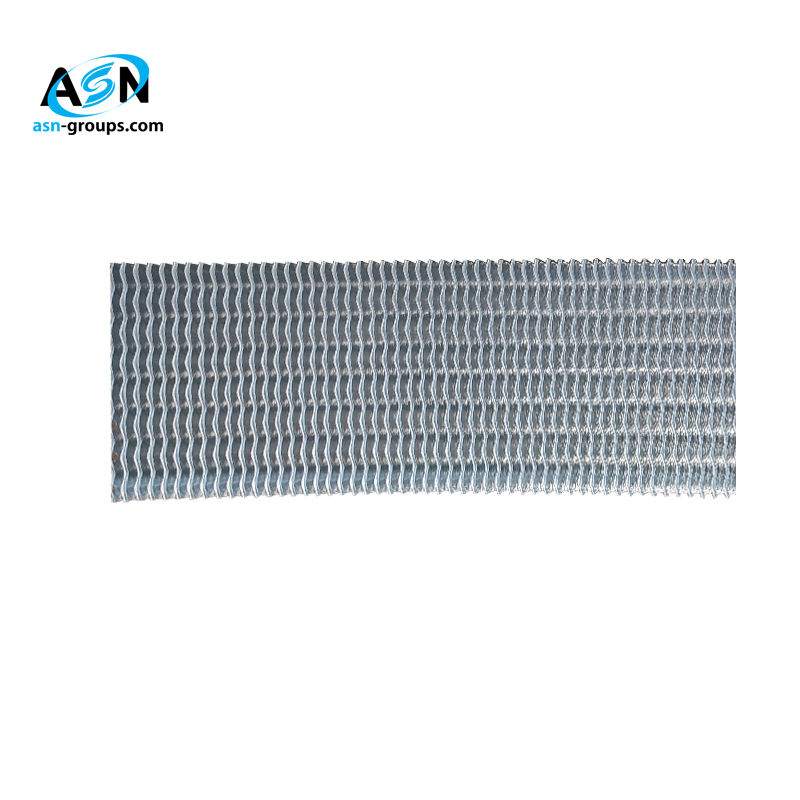

Microchannel design offers high heat transfer efficiency and compact footprint

-

Vacuum brazing ensures no flux residue, improving corrosion resistance and joint integrity

Applications

Ideal for advanced air cooling systems such as HVAC, electronics cooling, power systems, and other industrial heat transfer scenarios.

Packaging & Delivery

-

Selling Units: Single item

-

Packaging: Secure export packaging (e.g., wooden boxes); specifics available upon request

Purchase Assurance

-

1-year warranty for peace of mind

-

Protected by thorough machinery testing and QC video inspection

-

Competitive, high-efficiency solution designed for industrial reliability

FAQ

1. What is the advantage of microchannel design?

Microchannel configuration provides higher heat transfer efficiency, smaller size, reduced refrigerant usage, and lower air-side pressure drop compared to traditional fin-tube exchangers.

2. Why is vacuum brazing important?

Vacuum brazing eliminates flux residue, resulting in clean, corrosion-resistant cores and superior joint strength.

3. Is inspection documentation available?

Yes, both a machinery test report and outgoing inspection video are provided, ensuring thorough quality assurance.