In the tough and detailed world of hydraulic machines, keeping the right temperature is key to work, efficiency, and life span. The hydraulic setup, as the strength source for many kinds of industrial and moving tools, relies on good thermal energy control. Out of many methods made for this aim, the Aluminum Oil-Cooled Hydraulic Heat Exchanger stands itself as one of the most steady and useful ways to cool that are used now.

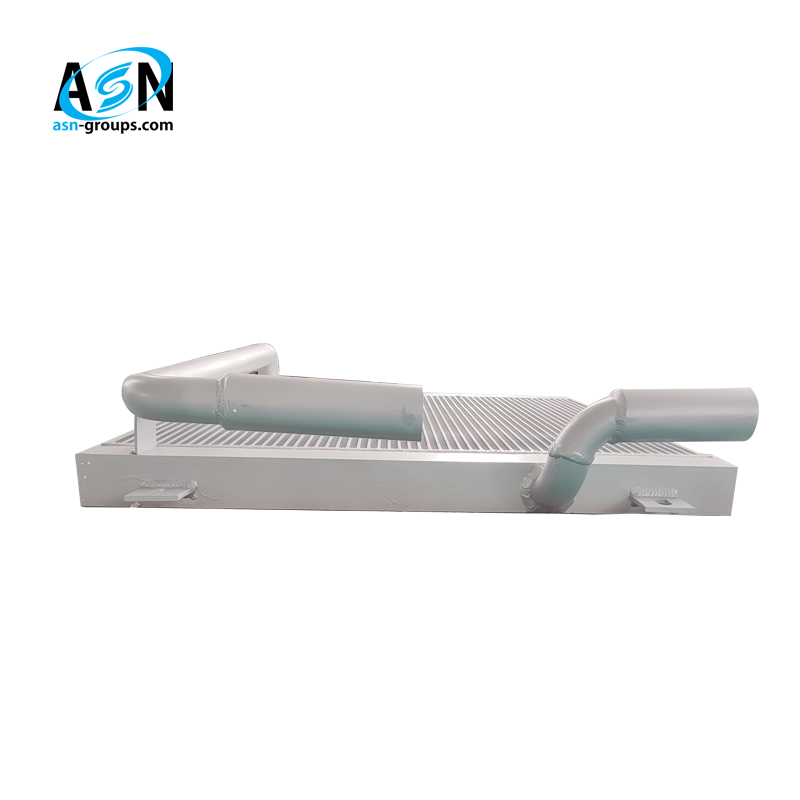

Made of top-grade aluminum, designed with oil cooling as its major function, this unit delivers accurate thermal management that allows systems to run smoothly even when they are continuously or heavily loaded. From agricultural equipment to woodworking machines, from large industrial pumps to low-energy refrigerators, this type of heat exchanger sits at the heart of consistent hydraulic performance.

The Role of Cooling in Hydraulic Systems

A hydraulic system cannot operate without generating heat. Mechanical friction, fluid shear, and pressure losses in pumps, motors, and valves all together with separately contribute to it. The safe operating range for most systems is approximately between 60–80°C. Above this range, the hydraulic oil starts losing its viscosity, which means lubrication efficiency will be reduced; more on component wear, plus an eventual failure of the system.

That is where the hydraulic heat exchanger comes into its own. Its function is to take away as much excess heat from the hydraulic fluid before it gets an opportunity to cause any damage. The more efficiently it can be done, the more efficiently the entire system can work. Aluminum oil-cooled heat exchangers do this by transferring thermal energy from the oil to either air or a cooling medium that surrounds it, and in this way, maintain constant, stable operating temperature.

Aluminum is a preferred choice because it has high thermal conductivity, is light in weight, and offers resistance to corrosion. It enables excellent heat transfer and, at the same time, keeps durability, plus eases installation in different setups of machinery.

Why Aluminum is the Preferred Material

When building a hydraulic heat exchanger, the choice of material largely defines its performance and lifespan. Out of metals- copper, steel, stainless steel, and aluminum; it is aluminum that has become the preferred material for most designs that are cooled by oil.

It conducts heat approximately three times better than stainless steel, allowing for a quick and much more efficient process of getting rid of heat. This denotes that the cooling process does not need as much surface area, hence a smaller and lighter unit.

Also, aluminum does not corrode. So even after long years of exposure to oil and moisture at different temperatures, it stays intact and functional. It is, therefore, more supportive of cheaper production and easier machining, adding to the total affordability of the heat exchanger, hence its availability.

In plate-type or fin-tube designs, aluminum allows proper adjustment of the flow of air and distribution of fluid, hence attainable high cooling performance at low pressure drop, which is a major parameter in hydraulic efficiency.

Oil Cooling Technology and Its Advantages

Oil cooling is preferred over water cooling in hydraulic systems for several reasons. Since oil is a good lubricant, it can be circulated with the same fluid used in the power transmission system, hence there will be no need to have separate loops for coolants.

Second, oil cooling systems generally do not support corrosion and contamination. Since the medium used for cooling is the same hydraulic oil, there will be no possibility of any cross-contamination or scale buildup, which is a common problem with water-based cooling systems.

Third, oil-cooled heat exchangers can work perfectly well in remote or dusty surroundings where these are construction sites, agricultural fields, or woodworking workshops also where water supply or maintenance resources are found to hinder the operation.

The Aluminum Oil-Cooled Hydraulic Heat Exchanger brings the best of both worlds: great cooling and low upkeep. It keeps a steady working heat, cuts down time lost to too much heat, and makes pumps, valves, and seals last longer.

Applications Across Industries

One of the defining characteristics of aluminum oil-cooled hydraulic heat exchangers is their versatility. They have become indispensable in a wide range of industries and applications:

- Сільськогосподарська техніка

Hydraulics perform the lift, steer, and drive duties of a tractor. These machines operate under extreme load conditions for extended periods in high-temperature outdoor environments. Proper oil cooling will ensure that there is no overheating in the hydraulic components, providing steady power output and avoiding degradation of the system. - Woodworking and processing machinery

Hydraulic systems operate saws, presses, and cutters. High-speed operations produce a lot of heat because friction plus the cycles of pressure that continue. An aluminum oil-cooled heat exchanger will stabilize hydraulic temperature, thus ensuring cutting performance remains as precise and also avoiding distortion of the equipment due to thermal expansion. - Industrial and Manufacturing Equipment

Injection molding machines, metal presses, and hydraulic presses all require stable temperatures to achieve repeatable accuracy. An oil-cooled system will make sure that the equipment runs within optimal thermal parameters, resulting in high productivity accompanied by long tool life. - Construction and Heavy Machinery

Heavy hydraulic machinery running without a break under varying loads needs Excavators, cranes, and concrete pumps to be fed by powerful hydraulics. Aluminum oil-cooled exchangers keep the oil from getting hot during heavy lifting or long running periods so that seals and hoses do not get damaged due to premature aging.

In wind turbine hydraulics and battery energy systems in containers, efficient oil cooling maintains the stability of high-density power units. By controlling the temperature of the oil, these exchangers contribute to energy efficiency as well as longer service intervals.

Engineering Design and Construction

The core shall typically be made up of several thin plates or tubes with fins on their surfaces, providing large areas for heat transfer. As the hydraulic oil moves through these passages, heat is then conveyed to the aluminum walls and finally to the ambient air by means of forced convection.

Some exchangers come with built-in fans or pumps, thereby boosting the cooling performance. The fan draws air across the fin surfaces, increasing the temperature gradient and improving heat dissipation.

It can be designed differently to suit the needs of an application— whether plate type, bar and plate, or tube and fin — they have one common goal: maximize heat transfer efficiency while minimizing energy consumption and pressure drop.

Manufacturers often integrate additional features such as:

-

Thermostatic control systems that automatically regulate fan speed

-

Overpressure protection valves for safety

-

Compact modular housings that fit easily into different hydraulic circuits

By using precision machining and rigorous quality control, aluminum heat exchangers achieve dimensional accuracy down to ±0.001mm, ensuring flawless assembly and consistent performance even under high vibration conditions.

Performance Benefits in Real Applications

The Aluminum Oil-Cooled Hydraulic Heat Exchanger offers several operational benefits that go beyond simple temperature control. These include:

-

Enhanced System Efficiency – Stable hydraulic oil temperature improves fluid viscosity, allowing smoother power transmission and higher energy efficiency.

-

Reduced Wear and Maintenance Costs – Overheating is a major cause of seal degradation, component wear, and system leaks. Cooling mitigates these issues, reducing maintenance intervals.

-

Extended Equipment Lifespan – By maintaining optimal temperature, the heat exchanger ensures that pumps, cylinders, and valves operate within safe parameters, significantly extending system life.

-

Improved Safety and Reliability – Stable hydraulic pressure reduces the risk of sudden failures, leaks, or operational hazards.

-

Environmental Sustainability – Aluminum’s recyclability and energy-efficient cooling performance contribute to a greener industrial footprint.

Energy Efficiency and Sustainability

Today, sustainability is not an ancillary aspect but rather the defining metric of performance in contemporary engineering. The aluminum oil-cooled heat exchanger adds up to environmental responsibility in several ways. First, just like all other metals, the extraction process of aluminum requires massive energy.

Also, good heat control leads to less energy waste. When the machine parts stay at even heats, power loss from thickness changes is stopped. This will directly show as lower fuel use by diesel machines and also less need for electricity in industrial systems.

Longer lifespans of components mean less waste because replacements do not have to be made as often over a period. This helps fit circular economy principles into the manufacturing and heavy industry.

Challenges and Innovation Trends

Despite their advantages, aluminum hydraulic heat exchangers face several challenges, particularly when used in high-pressure or highly contaminated environments. Innovations in design and materials are addressing these limitations:

-

Advanced Coatings: New surface treatments enhance corrosion resistance and prevent fouling in dusty or chemical-rich conditions.

-

Hybrid Designs: Combining aluminum cores with stainless-steel manifolds allows for higher pressure resistance and durability.

-

Smart Thermal Control: Integration of sensors and IoT-based monitoring systems enables real-time temperature tracking, predictive maintenance, and adaptive cooling.

-

Compact Integration: With space constraints in modern equipment, manufacturers are developing slimmer, modular heat exchangers that can be integrated directly into hydraulic reservoirs or chassis structures.

As industries transition toward electrification and automation, these developments ensure that aluminum oil-cooled heat exchangers remain relevant and technologically advanced.

Market Adoption and Global Demand

A global hydraulic heat exchanger market is gaining massive momentum with increasing acceptance towards energy-efficient and automated machinery. Aluminum oil-cooled models record robust growth in intake from Europe and North America as well as the Asia-Pacific regions.

In agriculture, the shift towards intelligent tractors and precise seeding machines demands consistent and robust hydraulic energy sources. In construction, the advent of electrically powered excavators and loaders has opened up new opportunities for compact cooling systems. Leading this transformation are manufacturers such as ASN, CIMC, and other commercial suppliers from Jiangsu, China, who provide adaptable aluminum exchangers meeting global standards yet maintaining cost-effectiveness.

Industrial modernization is happening; decarbonization is taking place on a global scale. With this, aluminum oil-cooled hydraulic heat exchangers become parts of systems of the future.

Customization and Engineering Flexibility

One of the biggest advantages offered by aluminum oil-cooled heat exchangers is their adaptability. They can be designed to fit a wide range of equipment configurations and thermal requirements.

Customization options include:

-

Varying the core thickness for different heat dissipation rates

-

Mounting options for horizontal or vertical installation

-

Different fan voltages (12V, 24V, or 48V)

-

Flow capacity adjustments based on hydraulic circuit size

This flexibility allows manufacturers and OEMs to integrate cooling solutions seamlessly into their machinery, ensuring optimal system performance without design compromises.

Looking Ahead: The Future of Hydraulic Cooling

As industries accept automation, electrification, and digital monitoring, the future of hydraulic cooling will be about smart designs that are efficient and environmentally sustainable. The next generation of aluminum oil-cooled exchangers most probably will have sensor-based diagnostics for their thermal efficiency and fan performance, as well as oil quality in real time. This will make predictive maintenance—replacing components before they fail—and further drive downtime even lower.

Modular coolers will probably be seen in large industrial applications and allow places to grow or replace cooling components without a major shutdown. Continuous research on nano-coated aluminum surfaces promises to increase the rate of heat transfer with reduced stickiness as well as reduced corrosiveness, hence increasing the exchanger’s lifetime even when applied in the most severe conditions.

The Aluminum Oil-Cooled Hydraulic Heat Exchanger is not merely a cooling component but rather the core of hydraulic reliability and performance across various sectors. Maintaining precise management of oil temperatures safeguards machinery, improves operational consistency, and supports sustainable energy consumption.

Whether installed in agricultural equipment, woodworking apparatus, large construction vehicles, or industrial automation setups,

As equipment continues to improve and industries demand ever cleaner, smarter, more effective installations, the aluminum oil-cooled fluid changer will remain an important component in the evolution of business —quietly ensuring that power, prowess, and result go hand-in-hand.